Why did the Levees/Floodwalls Fail During Katrina?

.

Contributing Factors

.

- Katrina Storm Surge - increased pressure on bottom of canals & on levees &

floodwalls

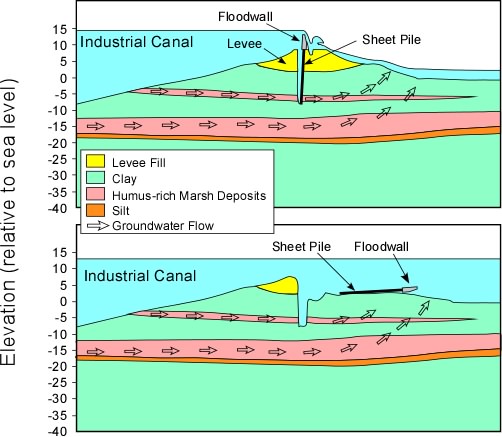

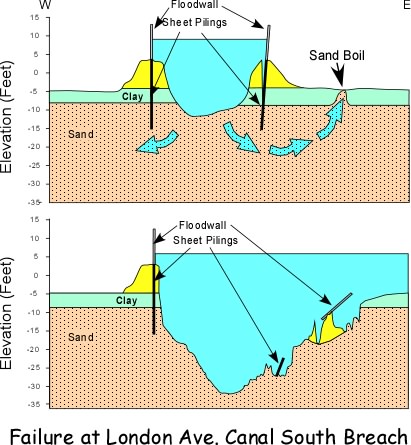

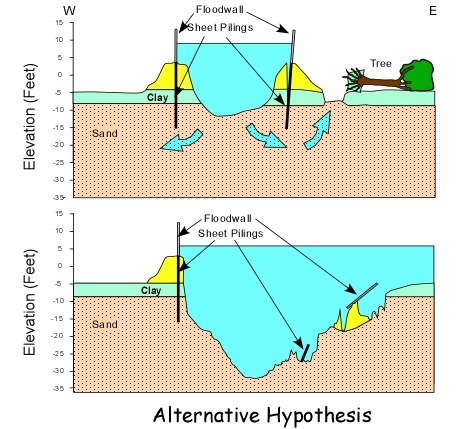

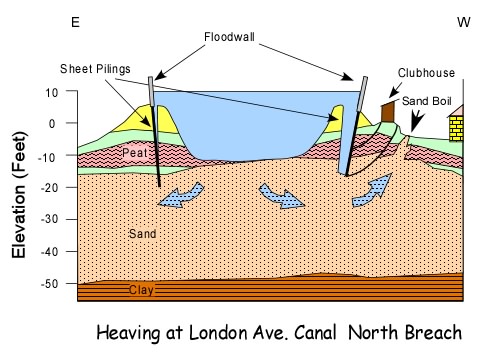

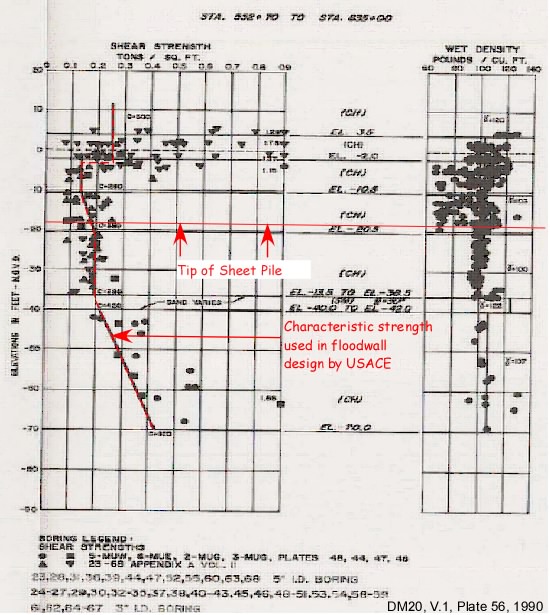

- Weak Materials in the foundations of the levees and floodwalls, such as Permeable Sands,

Peat, and

Weak Clay

- Trees uprooted by hurricane force winds

- No armoring of tops of levees to prevent erosion after overtopping

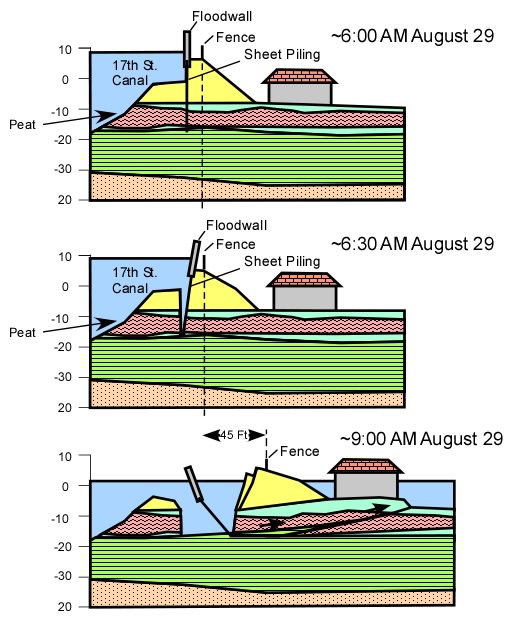

- Poor design of levees & floodwalls - did not consider all of the above!

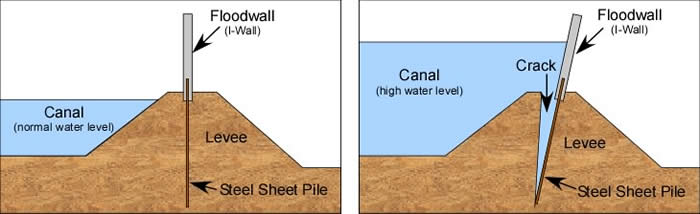

(I walls instead of T-walls, Low Factor of Safety, Short sheet pilings,

not enough consideration of complex and variable geological environment)

What could have prevented the failures? - Mitigation of Contributing Factors

- Storm Surge - Keep the Storm Surge Out of the Canals -

Gates at the mouth of Canals on Lake Pontchartrain

Pumps at Lake to pump water over Lakefront levees

- Weak Materials - Drive sheet pilings deep enough to cut off possible

seepage to outboard side of canals

Use T-walls instead of I-walls

- Trees uprooted by hurricane force winds - Don’t allow trees with roots that

may penetrate levees - remove existing trees

- No armoring of levees to prevent erosion after overtopping - Armor tops of

levees to prevent erosion

- Poor design of levees & floodwalls - did not consider all of the above!

Better oversight of design & construction of protection systems

Examples of Problems

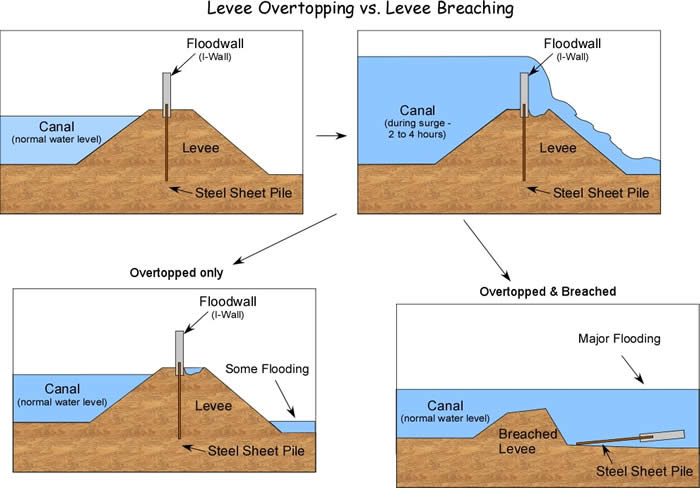

Levee overtopping, while it does allow water in to the protected area, is not as serious as levee/floodwall breaching (Figure 1)

Figure 1