Welcome

Our research interest lies in the general area of surface and colloidal science. We are mainly experimentalists with expertise in surface modification & patterning, self assembly, photolithography, micro- and nanofabrication, thin film deposition, tribology, and electrochemistry. Our research ideas rely heavily on biomimicry and bio-inspiration. Below are a few examples of ongoing projects in the areas of energy, health, environment and materials.

The Design and Fabrication of "Smart" Surfaces and Colloids

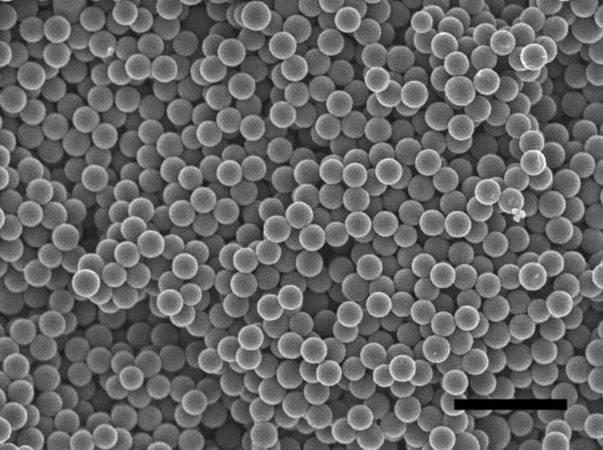

Lubricants play an integral role in the operation of several technologies and in biology, ranging from moving parts in machinery to the biolubrication of articular joints. The main purposes of a lubricant are to reduce friction and surface wear. We have found that an easily synthesized system composed of uniformly sized carbon microspheres use a "rolling" mechanism, similar to ball bearings, to provide excellent lubrication properties. Current work is focused on optimizing this system for a variety of applications.

Lubricants play an integral role in the operation of several technologies and in biology, ranging from moving parts in machinery to the biolubrication of articular joints. The main purposes of a lubricant are to reduce friction and surface wear. We have found that an easily synthesized system composed of uniformly sized carbon microspheres use a "rolling" mechanism, similar to ball bearings, to provide excellent lubrication properties. Current work is focused on optimizing this system for a variety of applications.

Design of Novel Biomimetic Technologies

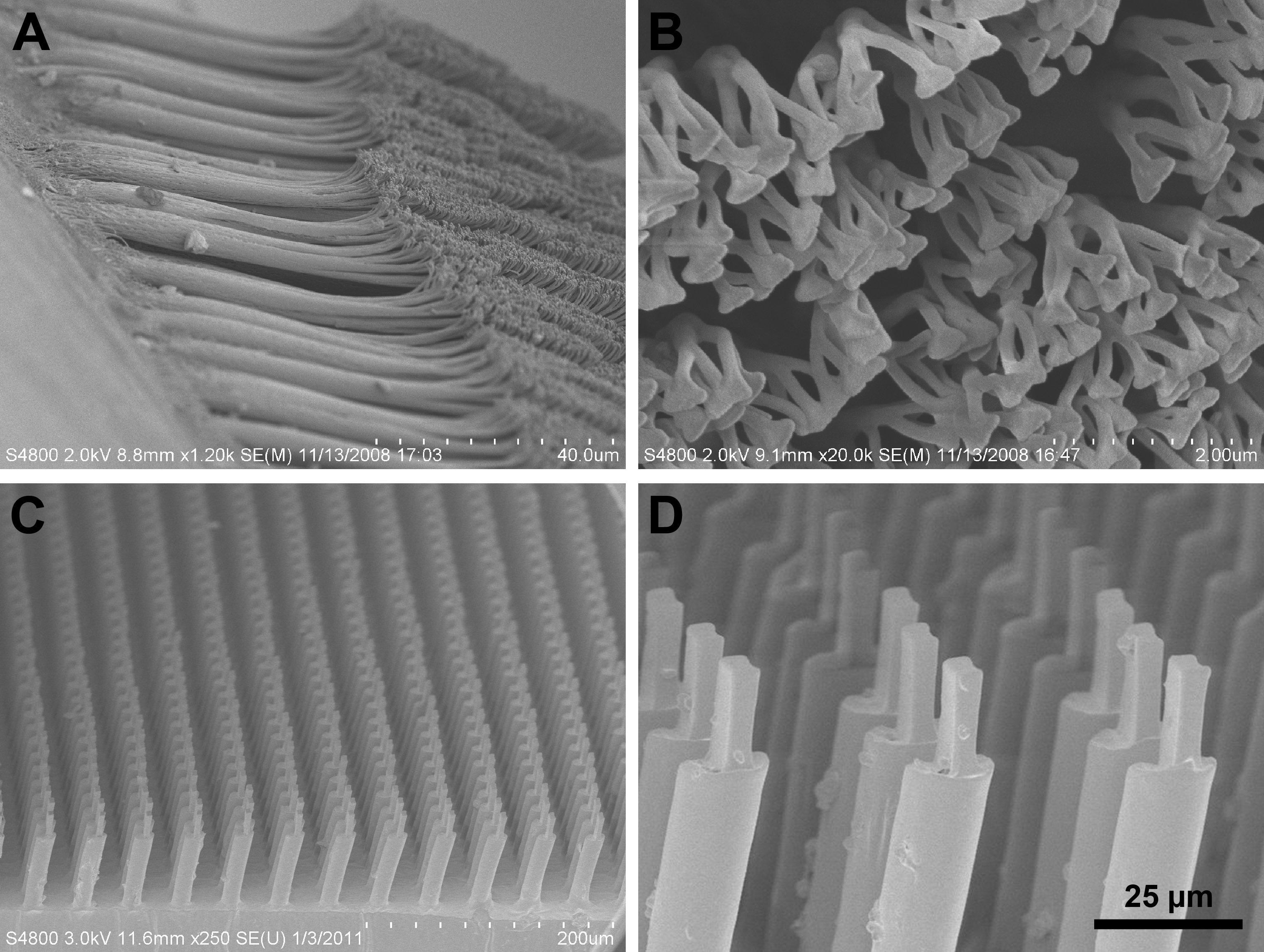

Nature has proven to be a tremendous resource for the development of novel technologies. As a result of evolution, several creatures have developed amazing abilities that are yet to be fully understood and reproduced. An example is the gecko lizard, which has the ability to run on walls and ceilings effortlessly. The fact that the geckos can adhere strongly to a surface and as importantly, detach easily, has made the gecko adhesive system an area of intense scientific interest. Although several aspects of the gecko adhesive system are understood, research is still needed to fully understand all of its capabilities. An adhesive mimicking the gecko adhesive system would have several potential applications including “smart” adhesives, sticky pads on robotic appendages, and friction pads in MEMS and would be operational in all types of environments including vacuum and liquids.

Nature has proven to be a tremendous resource for the development of novel technologies. As a result of evolution, several creatures have developed amazing abilities that are yet to be fully understood and reproduced. An example is the gecko lizard, which has the ability to run on walls and ceilings effortlessly. The fact that the geckos can adhere strongly to a surface and as importantly, detach easily, has made the gecko adhesive system an area of intense scientific interest. Although several aspects of the gecko adhesive system are understood, research is still needed to fully understand all of its capabilities. An adhesive mimicking the gecko adhesive system would have several potential applications including “smart” adhesives, sticky pads on robotic appendages, and friction pads in MEMS and would be operational in all types of environments including vacuum and liquids.

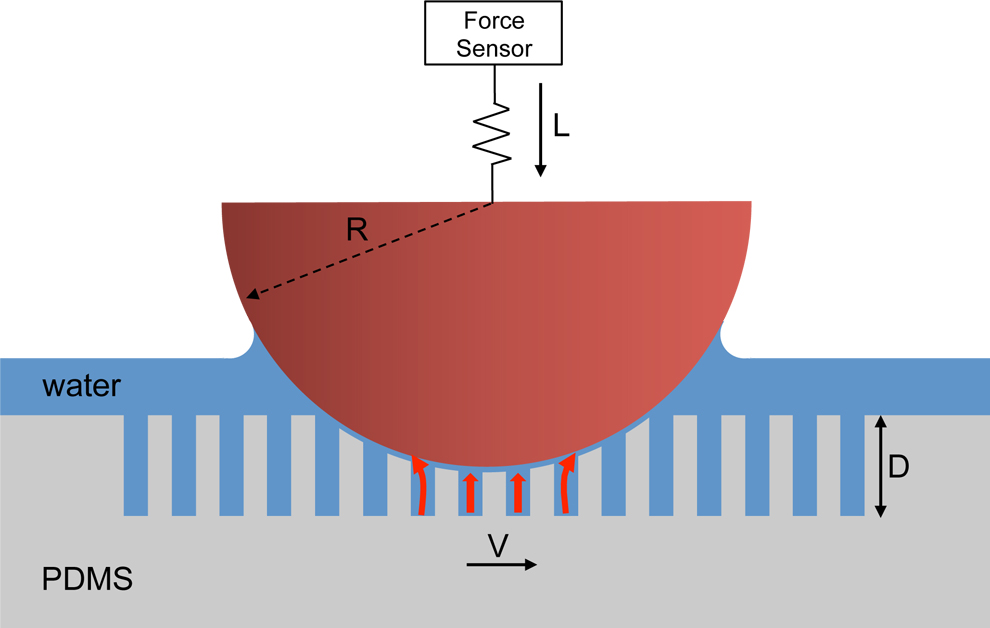

Another example of a biomimetic technology developed by our laboratory is a low friction surface. The technology was inspired by cartilage found in articular joints. We refer to this novel lubrication mechanism as the Load Induced Hydrodynamic Lubrication (LIHL) in which a localised load extrudes pressurized fluid from the pores of a compliant surface. The extruding fluid maintains a thin fluid layer between the shearing surfaces thus shifting the lubrication mechanism to a hydrodynamic regime. In this regime, friction can be ultra low. We propose to use this novel lubricating material in medical devices such as total joint replacement devices, catheters and contact lens.

Another example of a biomimetic technology developed by our laboratory is a low friction surface. The technology was inspired by cartilage found in articular joints. We refer to this novel lubrication mechanism as the Load Induced Hydrodynamic Lubrication (LIHL) in which a localised load extrudes pressurized fluid from the pores of a compliant surface. The extruding fluid maintains a thin fluid layer between the shearing surfaces thus shifting the lubrication mechanism to a hydrodynamic regime. In this regime, friction can be ultra low. We propose to use this novel lubricating material in medical devices such as total joint replacement devices, catheters and contact lens.

Morphological Control over Micro- and Nanocrystals

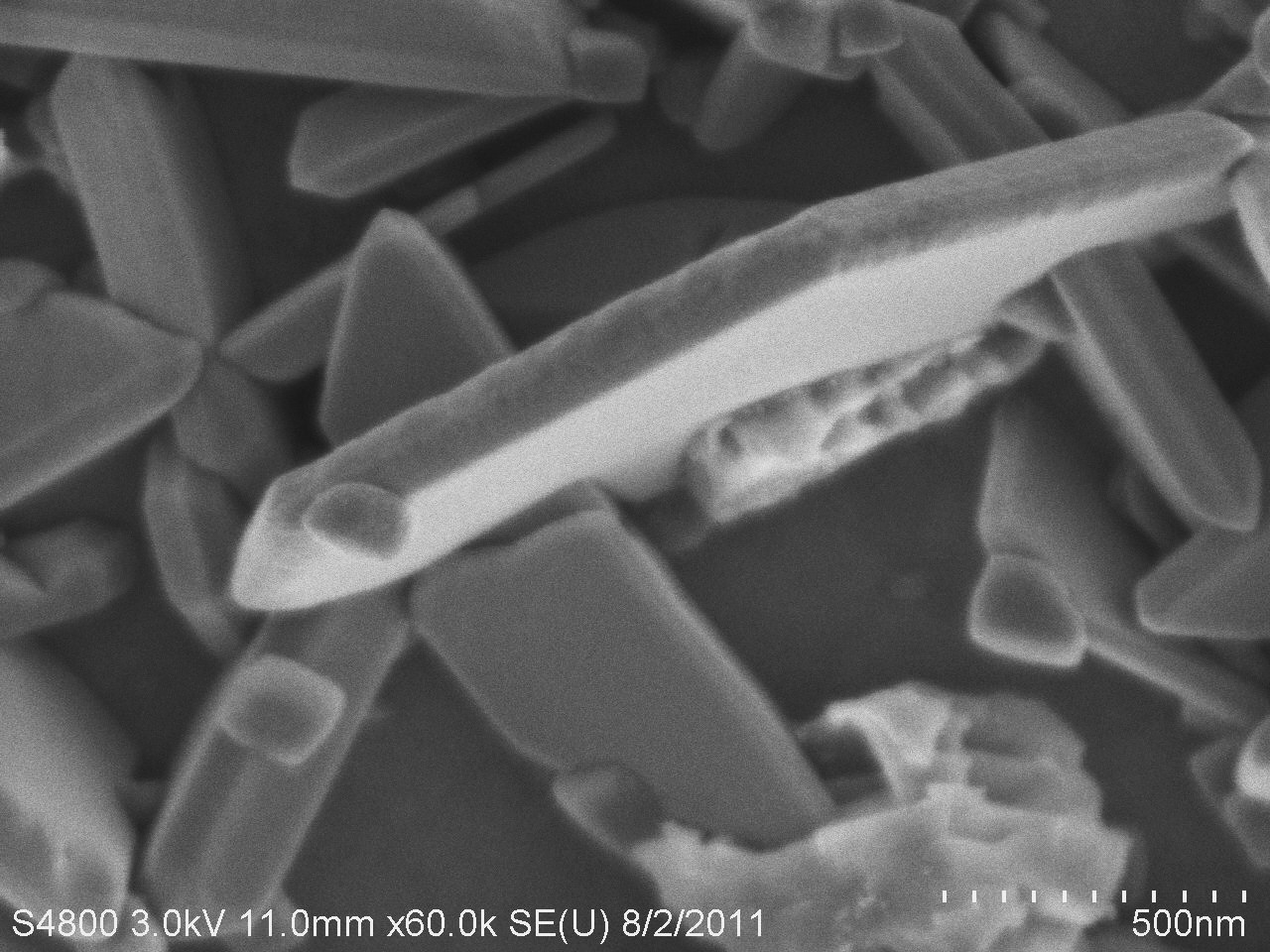

Nanotechnology, the field that is aimed at understanding and manipulating particles within the size range of 1-100 nm, has received intense scientific interest due to its application in a wide range of technologies ranging from data storage, spintronics, quantum computing, drug delivery, sensors, etc. Although several applications simply rely on making devices smaller, there are yet other applications that depend on the novel size-dependent properties of nanostructures. For example, the increased band gap of semiconductor nanoparticles (or quantum dots) results in emergent optical properties of the materials. Another example is the emergence of new magnetic properties in multicomponent nickel/copper nanowires. The electrical properties of carbon nanotubes have been found to change when exposed to a magnetic field. Even the thermal properties of nano-sized particles change as a result of the Kelvin equation; smaller crystals melt at temperatures lower than that of large crystals. As seen above, simply changing the lengthscale of materials can lead to dramatic changes in their optical, magnetic, electrical and thermal properties, which have led to and can potentially lead to new technologies. By changing the morphology of nanocrystals, multiple lengthscales are expected to influence their properties which can potentially lead to novel shape-dependent properties.

Nanotechnology, the field that is aimed at understanding and manipulating particles within the size range of 1-100 nm, has received intense scientific interest due to its application in a wide range of technologies ranging from data storage, spintronics, quantum computing, drug delivery, sensors, etc. Although several applications simply rely on making devices smaller, there are yet other applications that depend on the novel size-dependent properties of nanostructures. For example, the increased band gap of semiconductor nanoparticles (or quantum dots) results in emergent optical properties of the materials. Another example is the emergence of new magnetic properties in multicomponent nickel/copper nanowires. The electrical properties of carbon nanotubes have been found to change when exposed to a magnetic field. Even the thermal properties of nano-sized particles change as a result of the Kelvin equation; smaller crystals melt at temperatures lower than that of large crystals. As seen above, simply changing the lengthscale of materials can lead to dramatic changes in their optical, magnetic, electrical and thermal properties, which have led to and can potentially lead to new technologies. By changing the morphology of nanocrystals, multiple lengthscales are expected to influence their properties which can potentially lead to novel shape-dependent properties.

Carbon-based Materials

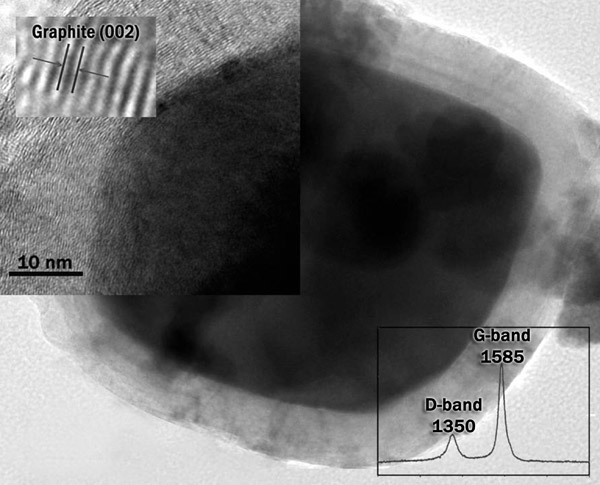

Our group is engaged in research and development of carbon materials including carbon nanotubes, carbon-encapsulated nanoparticles, and carbon spheres for a broad range of applications including supercapacitor, biomedical and lubrication applications. High specific surface area, high electrical conductivity, and high mesoporosity of carbon nanotubes make them ideal candidate for electrode materials of high-performance supercapacitors as high-energy and high-power sources for use in public transportation, consumer electronics, medical electronics, etc. Carbon-coated magnetic nanoparticles are promising candidates for biomedical applications like magnetic resonance imaging (MRI), drug delivery, and near-infrared (NIR) photothermal therapy. A graphitic shell on the surface of magnetic nanoparticles renders them biocompatible and prevents them from oxidation and dissolution in acidic environment. Our focus is on developing scalable and simple synthesis of the core-shell particles with high saturation magnetization with control over the shell thickness.

Our group is engaged in research and development of carbon materials including carbon nanotubes, carbon-encapsulated nanoparticles, and carbon spheres for a broad range of applications including supercapacitor, biomedical and lubrication applications. High specific surface area, high electrical conductivity, and high mesoporosity of carbon nanotubes make them ideal candidate for electrode materials of high-performance supercapacitors as high-energy and high-power sources for use in public transportation, consumer electronics, medical electronics, etc. Carbon-coated magnetic nanoparticles are promising candidates for biomedical applications like magnetic resonance imaging (MRI), drug delivery, and near-infrared (NIR) photothermal therapy. A graphitic shell on the surface of magnetic nanoparticles renders them biocompatible and prevents them from oxidation and dissolution in acidic environment. Our focus is on developing scalable and simple synthesis of the core-shell particles with high saturation magnetization with control over the shell thickness.

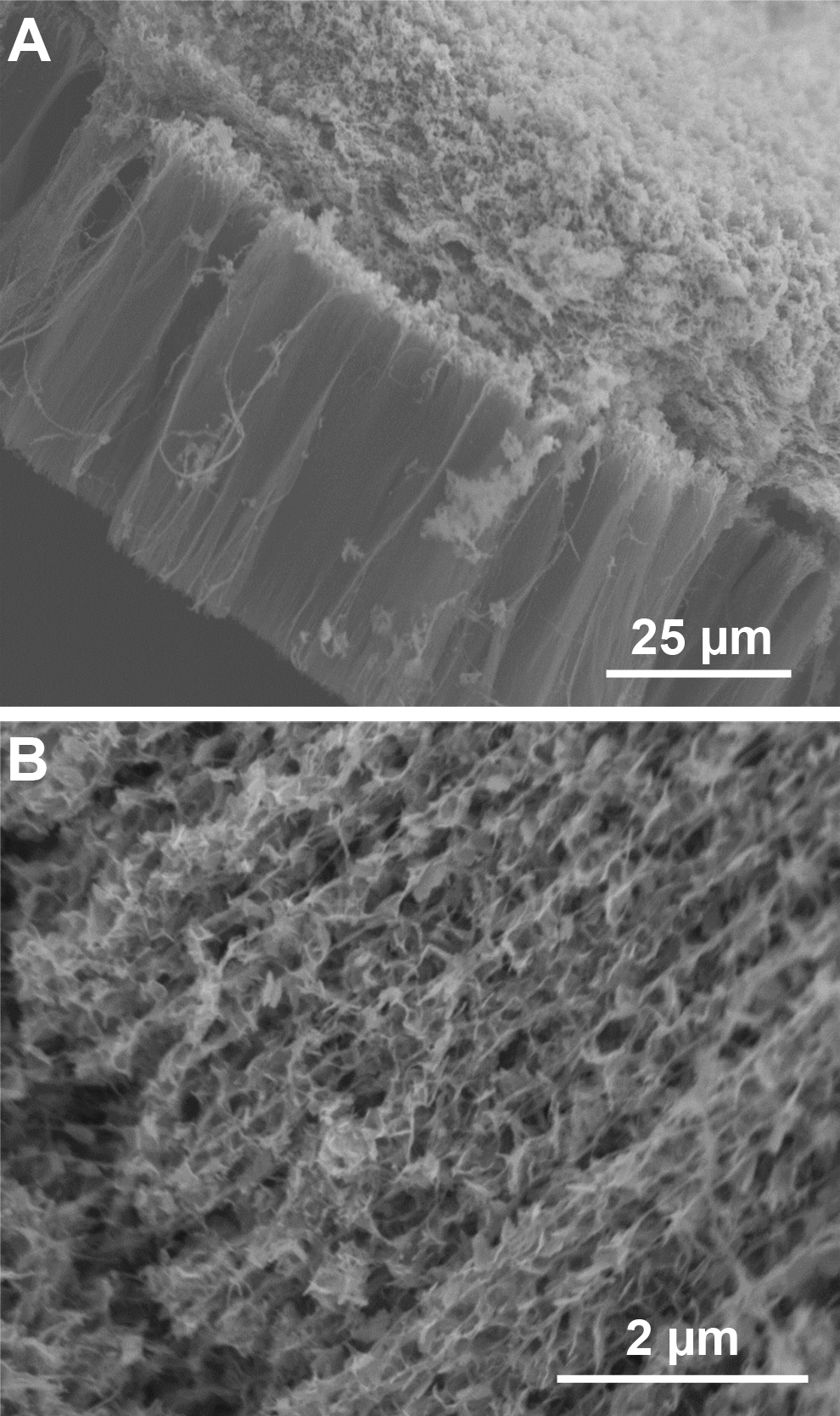

Faradaic supercapacitors have been proposed as a potential energy storage device that provides both high energy and power densities. The high specific surface area and good electrical conductivity offered by vertically aligned carbon nanotube (VACNT) arrays make them a promising candidate as faradaic capacitive electrode templates. Our laboratory has the expertise to synthesize VACNT using chemical vapor deposition. We are exploring the use of VACNT arrays as templates to deposit fadaraic materials such as nickel cobaltite. The high surface area of the active faradaic material exposed to the electrolyte solution allows for high current generation, fast charging and high cyclability of the hybrid supercapacitors. The latter properties are highly desirable for future generations of energy storage devices.

Faradaic supercapacitors have been proposed as a potential energy storage device that provides both high energy and power densities. The high specific surface area and good electrical conductivity offered by vertically aligned carbon nanotube (VACNT) arrays make them a promising candidate as faradaic capacitive electrode templates. Our laboratory has the expertise to synthesize VACNT using chemical vapor deposition. We are exploring the use of VACNT arrays as templates to deposit fadaraic materials such as nickel cobaltite. The high surface area of the active faradaic material exposed to the electrolyte solution allows for high current generation, fast charging and high cyclability of the hybrid supercapacitors. The latter properties are highly desirable for future generations of energy storage devices.

Interaction of Oil with Marsh Grasses

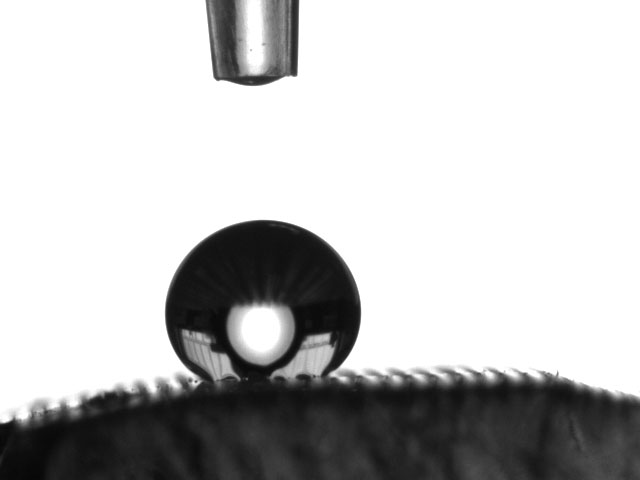

As a result of the recent deepwater oil spill which occured in the gulf, we are developing the next generation of dispersants which will not only serve to disperse oil but also prevent the oil from spreading on marshgrasses. The new dispersant formulation will rely on steric repulsive forces originating from polymers or nanoparticles to prevent the coalescence of dispersed oil droplets.

As a result of the recent deepwater oil spill which occured in the gulf, we are developing the next generation of dispersants which will not only serve to disperse oil but also prevent the oil from spreading on marshgrasses. The new dispersant formulation will rely on steric repulsive forces originating from polymers or nanoparticles to prevent the coalescence of dispersed oil droplets.

We would like to thank our sponsors: